Ceramic Heaters

714-890-0058

Ceramic heaters uniformly distribute temperatures up to 1100°F over diameters as large as 24″

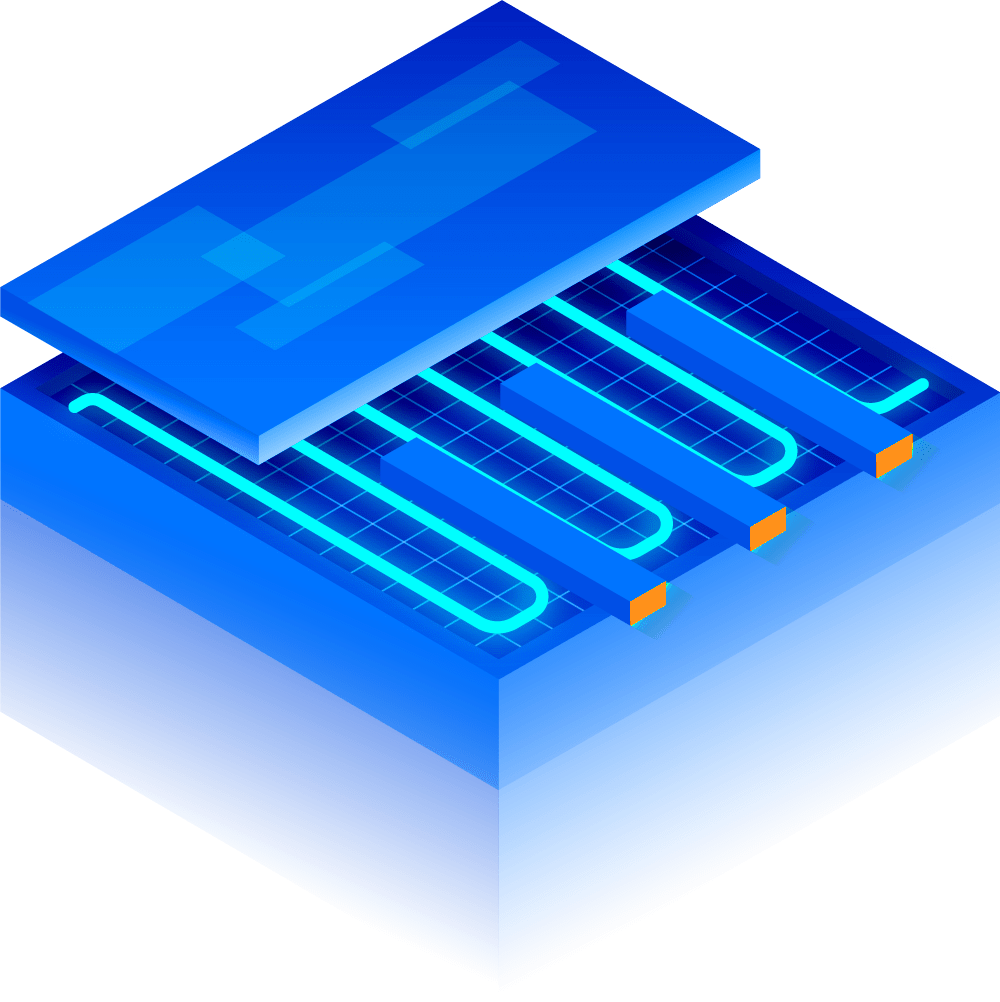

Developed for use in the semiconductor and process control industries, our ceramic heaters accommodate watt densities to 100W/sq. in. with proper heat sinking over the entire surface area. The heaters are constructed with a proprietary ceramic adhesive to maintain element registration in extreme temperatures without organic resins to eliminate outgassing at start-up.

Compressible ceramic leveling paper – die cut in the same configuration as the heater – is available to improve surface conformance and minimize thermal gradients between the resistive element and heat sink.

Available in thicknesses from .030″ to .060″, heaters can be designed to include integral RTD’s or thermocouple to optimize response time and gradient control.

Innovative Solutions

Problem: High temperature heater with uniformity over cycle range needed for “bed-of-nails” wafer testing equipment.

Solution: Created a mica heater with etched foil heating elements and varied watt densities to compensate for edge loss.

Ceramic Heaters Properties & Features

-

Temperatures to 1100°F

-

High Temperature Lead Wire Termination

-

Minimal Outgassing at Start-Up

-

Low Voltage/High Wattage

-

High Wattage/Low Voltage

-

Experts In Meeting Complex Geometric Configurations

Get Started

Ready to power up your next project? Contact us to explore our solutions and get started today!